Why We Developed FZN Technology

Why We Developed FZN Technology

By: Peter Kruse / Fri Mar 03 2023

Motivated by History

The first alternative to the traditional wood bat gained popularity in the 1970s, about 50 years ago. It started with basic aluminum as a more durable option to wood. The market incrementally progressed in that direction through today, with aluminum or more recently, polymer composite, being primary options.

In that time, wood was slowly disregarded and never seriously considered as a material for high performing bats. Beyond MLB, wood bats were relegated to wood bat leagues and for those that craved the classic feel, look, sound and tradition of wood.

Over the last 50 years, the large sporting goods companies and bat manufacturers dominated sales and continued the same fundamental approach from the 1970s. While making incremental improvements, they are still using legacy processes and materials when compared to today’s technology. With inertia in effect, and with no disruptive competition forcing a fresh perspective on the baseball bat, why change?

Delano Bat Company’s Heritage and Mission

Delano Bats has been in the bat business for many years. We were in the solid wood market and heard many of our loyal customers telling us they didn’t particularly like the feel or sound of their alloy or composite bats but had no other options without sacrificing performance.

We were motivated by our customers and the realization that the history and aesthetic design components of the traditional baseball bat were being completely neglected in the chase for performance, and bats were still stuck in circa 1970s era thinking. There was no product in the market attempting to bridge between the old and the new, which became our mission, to fuse together the history of baseball (wood) with the most modern construction materials (composites) to give hitters the benefits of both.

Without being tied to legacy techniques or technologies and with a fresh perspective and a commitment to baseball’s heritage, we patented FZN Technology - a fusion of tradition and technology.

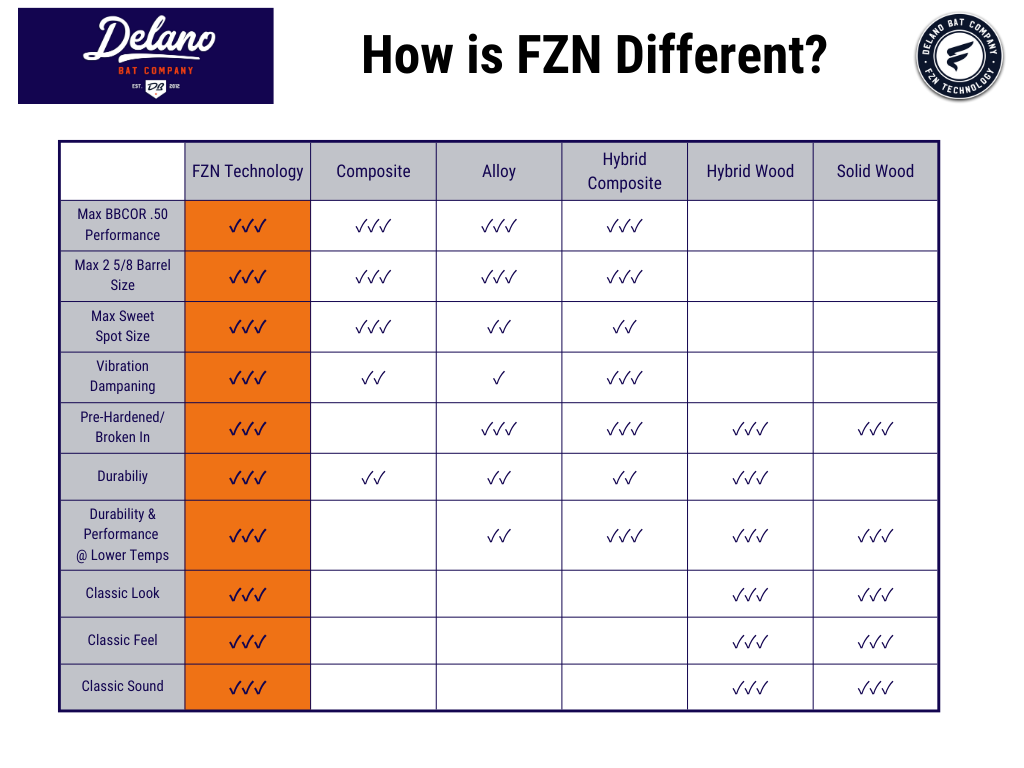

How is FZN Different?

FZN is different in the intent of the product and its material construction:

- FZN uses wood as the hard hitting surface and composite materials for strength, durability, balance, barrel size and performance. This gives it a wood look and sound, but produces the barrel size, performance and durability expected from maximum allowable BBCOR specs.

- Traditional BBCOR uses composites and metal alloys interchangeably for the hard hitting surface, strength, durability, balance, barrel size, and performance but lacks the feel, look and sound of classic wood.

- Hybrid wood bats have emerged more recently, using wood as the hard hitting surface and composite materials for strength and durability. There are no additional effects to aid performance, only to reinforce the bat to make it next to unbreakable. The bat will look, feel, and perform just like wood, but there are no consequences for getting jammed.

Here is a summary level view of how FZN is different: