The Road to BBCOR is filled with pitstops

By: Kathy Sonier

Jun 21 | 2024

As you know, Delano Bat Company has submitted the latest prototypes of our flagship FZN Technology bat, The Original Gamer, to Washington State University (WSU) for testing and BBCOR Certification. Most of you also know that that OG submission failed to meet the Batted Bat Coefficient of Restitution (BBCOR) threshold of .50 by .002. Soooo close! Since that submission, we have additional testing data, and we want to share an update on our summer road trip to WSU.

BBCOR is more than a stamp on a bat. The sports lab at WSU has an exclusive and elaborate standardized testing process to ensure that bats used in games meet certain standards to keep players safe. While there are many opinions about BBCOR and its effect on the game, the standard was implemented to reduce the performance of increasingly hot metal bats and bring them closer to the performance of wood. If a hitter is playing in high school or college, they are swinging BBCOR. So, all roads to the plate go through WSU and the BBCOR Certification process.

When FZN Technology was first developed, a proof of concept bat was submitted to WSU late in 2020, and the bat failed the test out of the gate for too much pop. This was great news for the founders – we knew we could generate the performance that elite hitters are looking for with the look and sound of wood – we just needed to adjust some things. That has been our journey ever since. As a boot-strapped start-up, we have taken many scenic overlooks on the road to BBCOR to take in the learnings and gain inspiration from players who’ve swung our prototypes. The trip has also had its share of rest stops to re-fuel the bank account and re-jigger the plan.

Delano Bat Company has been to WSU and back a few times with our newest prototypes, and we want to share our latest data and plans to get The Original Gamer certified and into the hands of anxiously awaiting hitters.

Trip #1 – SOOOO close:

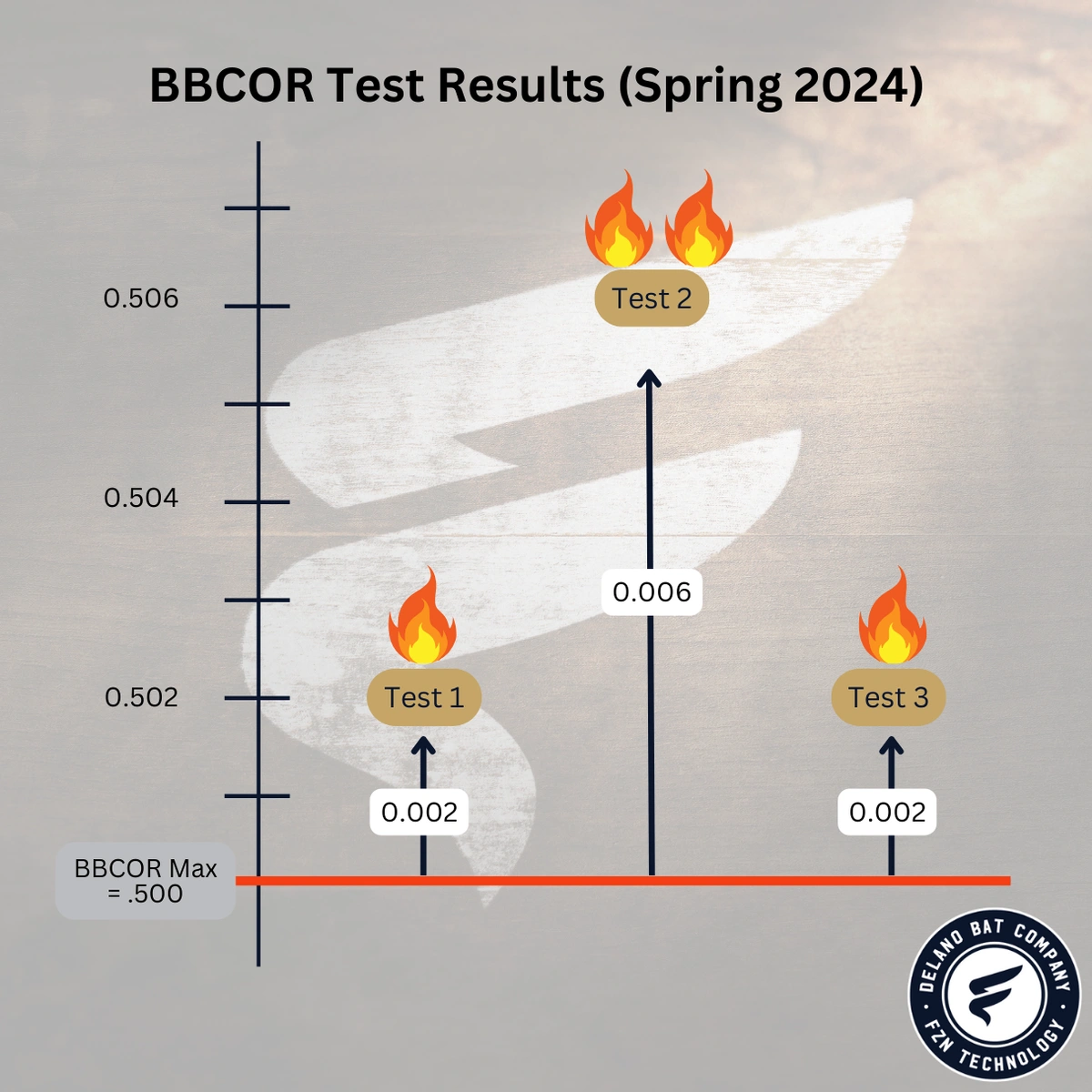

Our first re-submission since proof of concept was heart-breakingly and excitingly close to max BBCOR spec of .50. Two-one-thousands (.002) separated The OG from passing. It was just a smidge too hot to be approved, but we were pumped to get so close, and we hypothesized what was needed to dial down the heat just a tad.

Trip #2 - Wrong turns happen:

The tech team was so excited by the near-miss that they dropped everything (ie, their day-jobs) and re-submitted quickly making the hypothesized adjustments. It turns out that hasty hypotheses are no match for measured steps. The results of that 2nd submission came back, and the FZN got even hotter. We took a wrong turn on the scale: from .502 up to .506 - still close, but a .004 swing in the wrong direction.

Trip #3 – The Scenic Route:

While the shortest distance between 2 points is a straight line, sometimes we end up on the scenic route. The team realized how they overswung with the 2nd submission and re-engineered the tech using a more measured approach, however the surprise of increasing the pop too much on try #2 may have affected the extent of the next round of tweaks. The result for the 3rd submission was a .502 - maybe not quite driving in circles, but certainly not a straight line to certification.

First Attempt In Learning (F.A.I.L.):

Failure is not a dirty word, especially when you learn from it. Anyone who’s steered the entrepreneur-ship and headed towards start-up land knows that nothing goes according to plan, and that failure is to be expected and cherished in those early stages. You don’t learn much if you get it “right” the first time. After all the tech team has learned from these recent submissions, there are new hypotheses and new plans to reach BBCOR Certification, with an even better bat than originally designed. That is the magic of test & learn.

The good news is that there are plans A, B and C. Each with its own timeline and work stream to reach certification.

The bad news is that these are not fast fixes like the first 2 tweaks. These new product adjustments require tooling and equipment, which take time. They need additional raw materials which cost money. Both of which are precious resources for a pre-revenue start-up.

We planned to be in market this month when we first submitted The OG at the beginning of May, but we have to shift that timing expectation back a few months to be conservative. We hope to be producing 3rd generation prototypes in a month, then internal testing, then submission, and then hopefully launch-ready product... If we launch around the Fall ball season, we can still have hitters swinging FZN Technology this year.

Thanks for the fuel!

We receive weekly notes and emails from our followers asking about timing for launch and expressing excitement for FZN and The OG. We are motivated not only by our passion for this evolution in baseball bat technology, but also by your enthusiasm for the work we are doing. Thank you for reminding us why we are on this crazy journey. While it may be a long and winding road, we are energized by the sites and experiences along the way. We’ve truly enjoyed getting to know our fellow travelers this past year (so please keep those emails and notes coming), and we look forward to spending some quality time at our first destination of BBCOR certification before the next journey begins.